8 Tips to Make Your PCB Assembly a Success PCB HERO Circuit Diagram The integration of advanced PCB prototyping, assembly, and eco-friendly manufacturing practices is pivotal for driving innovation and efficiency in the engineering sector. As technologies like IoT, 3D printing, and AI reshape design and production processes, PCBs are becoming more compact, energy-efficient, and adaptable to meet the demands of

Discover the comprehensive guide on the PCB assembly process, from component procurement to final testing. Learn best practices, challenges, and future trends to enhance your PCB assembly efficiency and quality. Perfect for professionals seeking to optimize their electronics manufacturing process.

The Most Comprehensive Guide to Printed Circuit Board Assembly Circuit Diagram

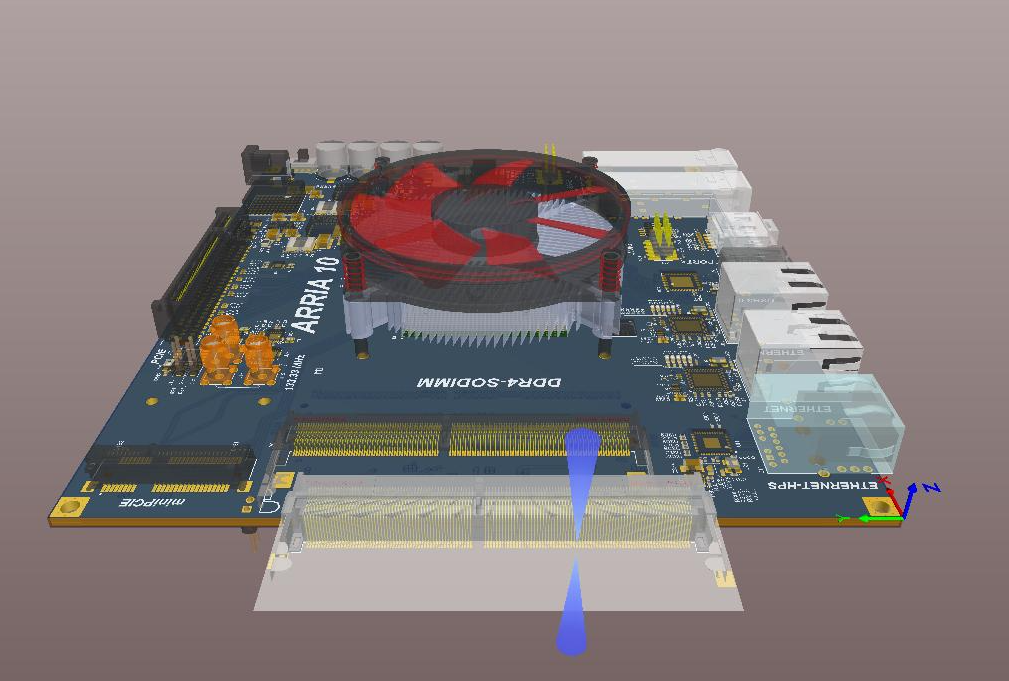

Building a PCB requires precision and expertise. In this guide, we break down the entire PCB assembly process, highlighting best practices to ensure high-quality results. PCB circuit board assembly is an important method in the production of electronic devices. Whether it is smartphones, scientific devices, or car systems, the printed circuit

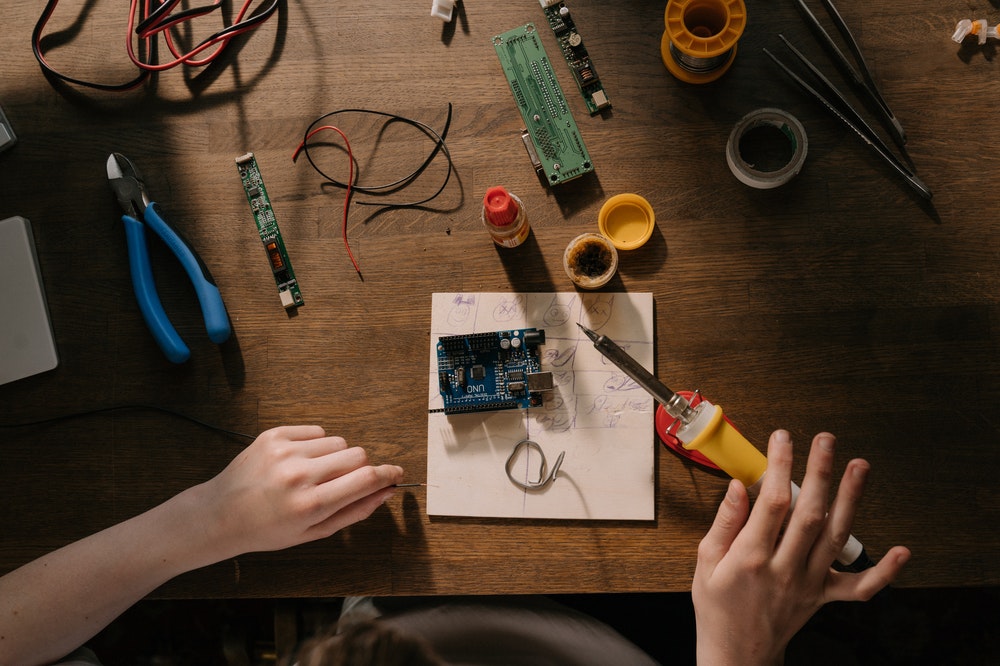

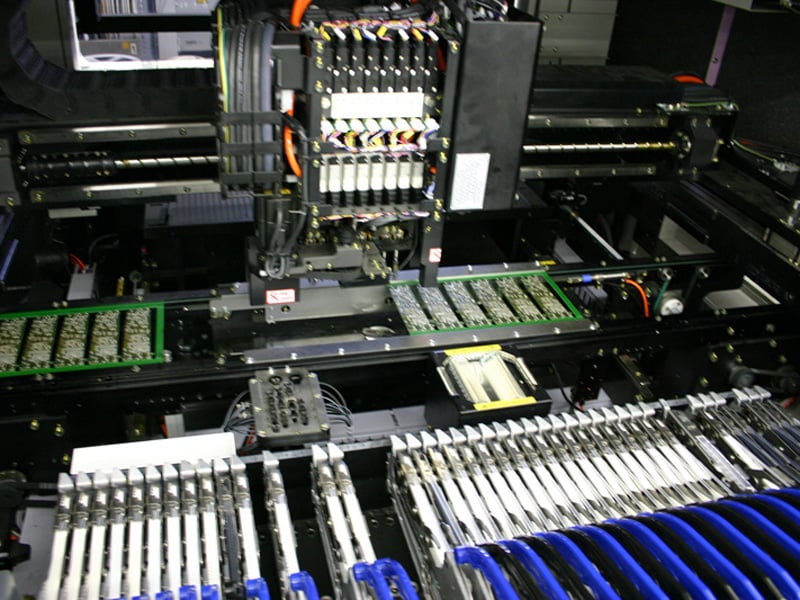

Best Practices for High-Quality PCB Assembly. Design for Manufacturability (DFM) One of the most critical factors in ensuring efficient and high-quality PCB assembly is Design for Manufacturability (DFM). DFM involves designing PCBs with manufacturing capabilities and limitations in mind, which helps avoid production issues, reduce errors, and Best Practices in PCB Assembly. To ensure high-quality and reliable PCB assembly, consider the following best practices: Design for Manufacturability (DFM) Design your PCB with manufacturing in mind, adhering to guidelines for component placement, trace routing, and clearances. This helps minimize assembly issues and improves production efficiency. The PCB Assembly Process: Step-by-Step Breakdown. Understanding the pcb assembly process is crucial for achieving high-quality results in your electronic projects. The journey begins with design; a well-crafted schematic lays the foundation for successful pcba (printed circuit board assembly). Following this, the next step involves selecting the appropriate materials, including components

PCB Prototyping and Assembly: Best Practices for Engineers in High ... Circuit Diagram

Best Practices for Successful PCB Assembly. To ensure a smooth PCB assembly process and avoid potential pitfalls, here are some best practices: 1. Optimize Your Design for Manufacturability (DFM) Design for manufacturability (DFM) is essential in minimizing errors during the PCB assembly process. Simplifying your design, reducing tight Key Takeaways. Effective PCB assembly and PCBA processes require a strategic combination of material expertise, precision techniques, and rigorous validation. Durability begins with selecting substrates and laminates that match operational demands, such as high-frequency FR-4 or polyimide for thermal resilience. In precision soldering, controlled reflow profiles and solder paste viscosity are

Key Components in PCBA Assembly. In the realm of PCBA (Printed Circuit Board Assembly), understanding the key components is vital for ensuring effective production processes.At the core of any PCB assembly are components such as resistors, capacitors, integrated circuits (ICs), and connectors.These elements play a crucial role in defining the functionality and reliability of the electronic