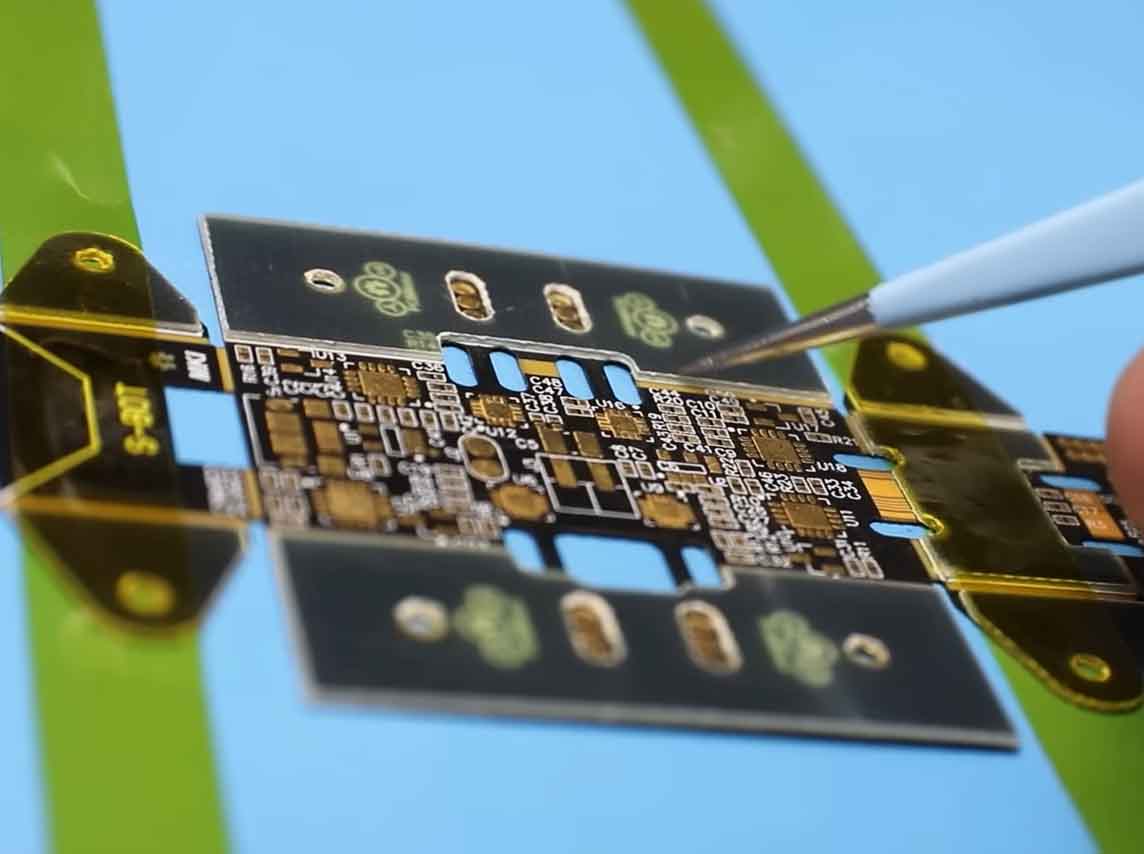

FOLDABLE PCB Robot Circuit Diagram How to Build a Robot - PCB Design; Project How to Build a Robot - PCB Design November 02, 2015 by Travis Fagerness. Part two of a series of articles on building a robot that can follow lines or walls and avoid obstacles! This time we'll be covering PCB design. Start building a robot that can follow lines or walls and avoid obstacles! The field of robotics PCB design and manufacturing is at the forefront of technological innovation, constantly evolving to meet the demands of increasingly sophisticated robotic systems. From

Since the PCB must work to control the robot, robot builders cannot compromise on the design and structure of the PCB. Get Pricing and Lead Time Call 717-558-5975. Design Considerations for PCBs for Robotics. The PCB starts with a schematic. This design phase is crucial for outlining the components and arrangement on the circuit board. Compact and Space-Efficient Design: Space, in most robotics applications, is constrained, and this, in most cases, implies that power systems shall be designed with a small size and a compact and novel space-efficient layout. Here, the power supply system may be built using multi-layer PCBs or flex-rigid designs that can help in increasing Learn Robotics is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a way for websites to earn advertising revenues by advertising and linking to Amazon.com. Step 2: Pick a Software to Design PCB Files. It doesn't really matter which software you use to design circuits and

The Role of Flexible PCB Design in Next Circuit Diagram

PCB Design Considerations for Robotics. Designing PCBs for robotic applications involves several key considerations to ensure optimal performance, reliability, and functionality. Some essential factors to consider include: 1. Component Selection. Selecting the right electronic components is crucial for the success of a robotic PCB design PCB Design Considerations for Robotics. When designing PCBs for robotics, several factors must be considered: Heat Management: Effective heat dissipation is crucial to prevent overheating and ensure longevity.; Durability: PCBs must withstand physical stress and environmental factors, especially in industrial or outdoor robotics.; Signal Integrity: Maintaining signal clarity and strength is

Here are some key challenges faced in robotics circuit board design: Durability and Reliability: Robotics often operate in harsh environments, such as industrial settings or outdoors. PCBs must be designed to withstand these conditions, including temperature extremes, moisture, and vibration, while maintaining reliable performance. This article will explore how flexible PCB design is transforming robotics and what that implies for PCB manufacture. Why Robotics Need Flexible PCBs Unlike conventional rigid PCBs, flexible PCBs are designed to bend and twist, which creates countless opportunities for integrating electronics into the intricate forms and motions needed for Robotics Tutorials. 1. Orientation 1. Sensor Calibration Accelerometer Magnetometer Gyroscope 2. PCB Design This section goes over the fundamentals of PCB board design by creating an odometry measurement board. We will be going through the complete processes from concepts, design, and part sourcing to PCB footprints and layouts.